What Is TPE?

TPE is a class of polymers that combine the elasticity of rubber with the processability of plastics. It can stretch and return to its original shape like rubber, but also be melted, reshaped, and recycled like thermoplastics.

Properties

- Elasticity & Flexibility: Rubber-like stretch and rebound

- Processability: Moldable via injection molding, extrusion, blow molding

- Chemical & UV Resistance: Stable in harsh environments

- Soft Touch & Comfort: Ideal for skin-contact products

- Wide Hardness Range: Customizable from soft to firm

- Recyclability: Can be reheated and reused

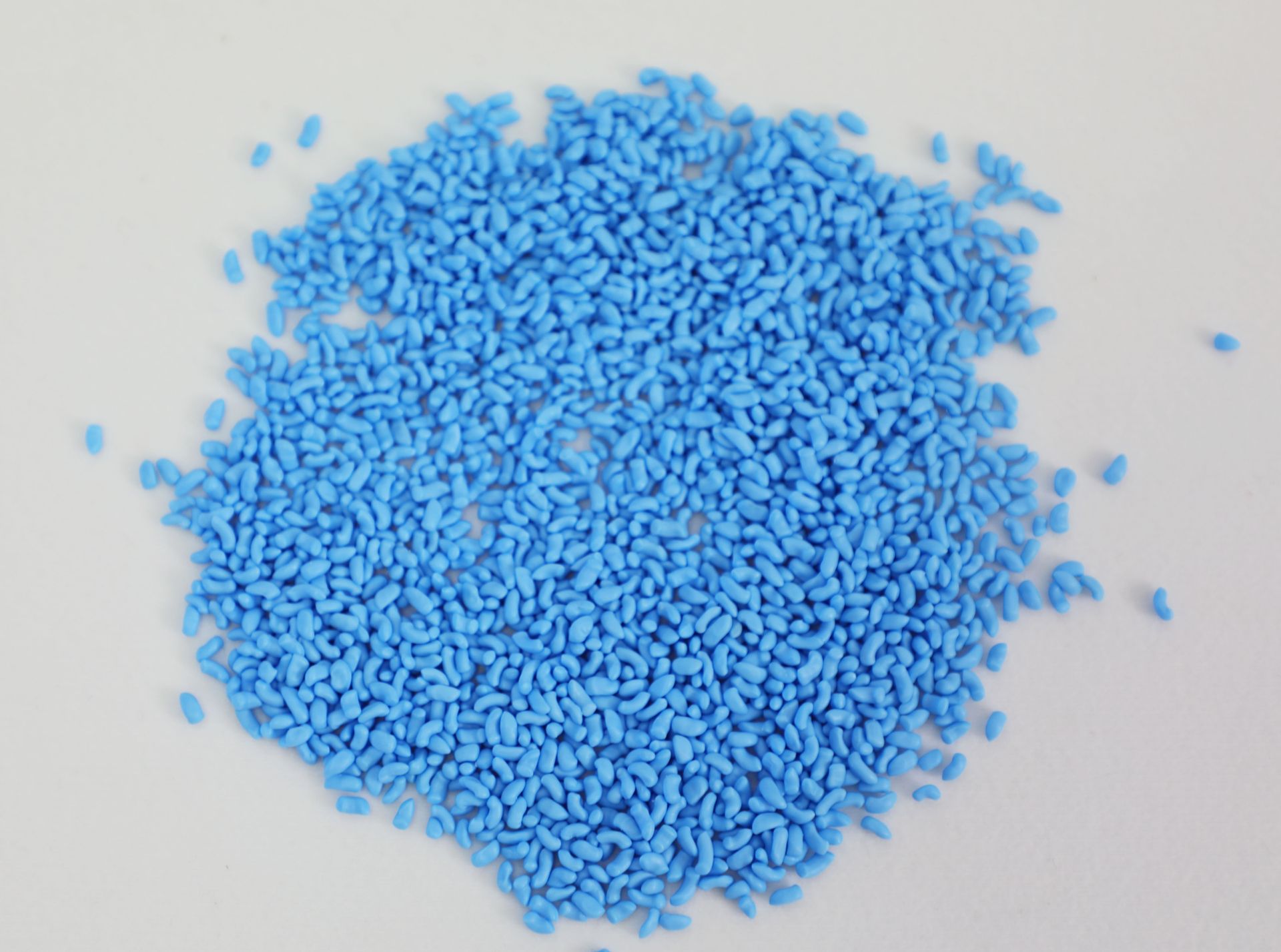

- Colorability: Accepts dyes and pigments well

Advantages

- Efficient Processing: No vulcanization needed; short cycle times

- Eco-Friendly: Recyclable and energy-efficient to produce

- Safe: Latex-free and non-toxic—suitable for medical and food use

- Consistent Quality: Minimal batch variation

- Cost-Effective: Lower production costs than traditional rubber

Disadvantages

- Thermal Sensitivity: May deform at high temperatures

- Wear Resistance: Lower than some conventional rubbers

- Solvent Sensitivity: Vulnerable to oils and greases

- Environmental Recovery: Actual recycling rates may vary

Applications

Automotive

- Weatherstripping, floor mats, gaskets, seals

Medical & Healthcare

- Tubing, grips, hypoallergenic components

Electronics & Appliances

- Soft-touch grips, wristbands, connectors, cable sheaths

Consumer Goods

- Toys, toothbrushes, kitchenware, folding buckets

Construction

- Door/window seals, expansion joints

Industrial Equipment

- Anti-vibration mounts, gaskets, shock absorbers

Food Packaging

- Flexible containers, seals, additives