What Is TPU?

TPU is a thermoplastic elastomer known for its flexibility, durability, and resistance to abrasion and chemicals. It’s made from a block copolymer structure with alternating hard and soft segments, allowing it to be both tough and elastic.

Properties

- High elasticity and flexibility

- Excellent abrasion and wear resistance

- Good chemical and oil resistance

- Transparency and colorability

- Wide hardness range (Shore A to Shore D)

- Low-temperature performance

- UV and weather resistance (especially aliphatic TPU types)

- Processable via injection molding, extrusion, and 3D printing

Advantages

- Combines rubber-like flexibility with plastic-like strength

- Excellent durability in harsh environments

- Recyclable and moldable like other thermoplastics

- Suitable for precision parts and soft-touch surfaces

- Available in medical-grade and flame-retardant variants

Disadvantages

- Higher cost compared to simpler TPEs

- Poor high-temperature resistance—can soften or deform under heat

- UV sensitivity in some grades (though aliphatic TPUs resist discoloration)

- Requires careful processing to avoid degradation

Applications

TPU’s versatility makes it ideal across many industries:

Automotive

- Gear knobs, instrument panels, seals, and console parts

Footwear

- Soles, midsoles, and flexible components

Consumer Electronics

- Phone cases, keyboard protectors, and wearable bands

Medical

- Tubing, catheters, and flexible connectors

Industrial

- Hydraulic seals, gaskets, hoses, and cable jacketing

Textiles & Apparel

- Coatings for waterproof fabrics, inflatable materials, and adhesives

Agriculture

- Animal ID tags and weather-resistant components

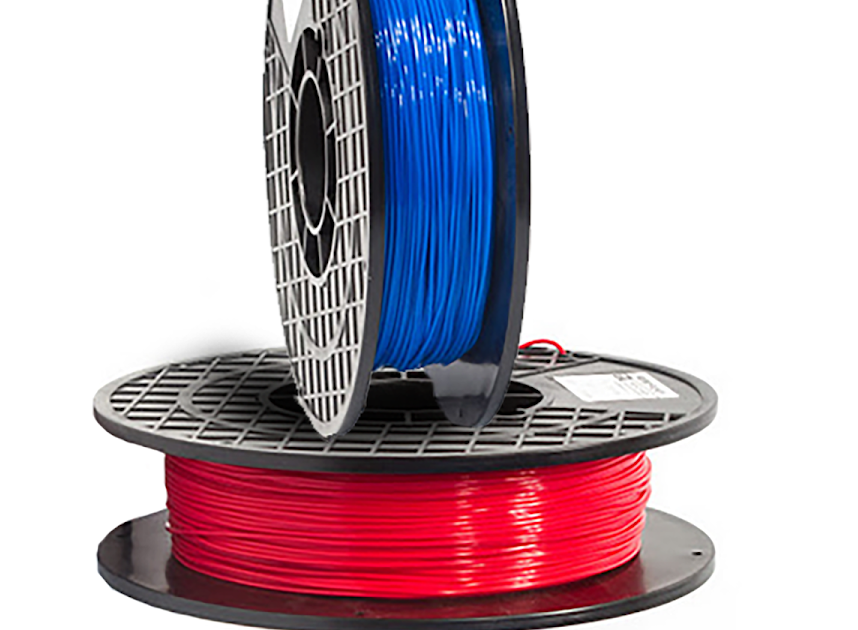

3D Printing

- Flexible filaments for FDM and powders for SLS