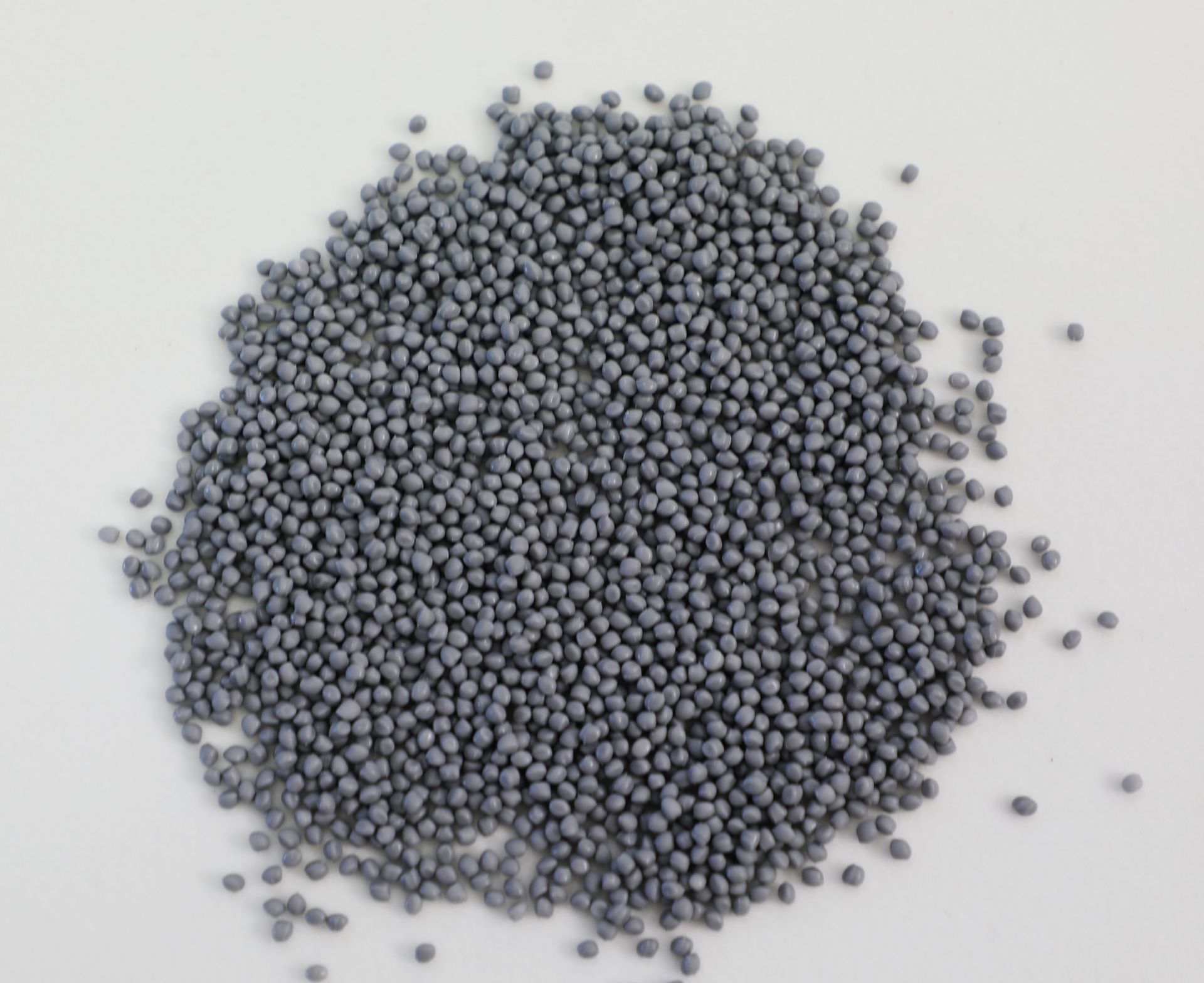

What Is TPR?

TPR is a thermoplastic elastomer that blends the elasticity of rubber with the moldability of plastic. It’s typically made from styrenic block copolymers (SBCs) and can be processed using standard thermoplastic techniques like injection molding, extrusion, and blow molding.

Properties

- Elasticity & Flexibility: Comparable to natural rubber, with excellent rebound.

- Durability: Resistant to wear, abrasion, and weathering.

- Chemical Resistance: Withstands oils, acids, and alkalis.

- Temperature Range: Typically functions between -40°C to 100–120°C.

- Lightweight & Non-toxic: Safe for food-grade and medical applications.

- Recyclability: Can be reheated and reshaped, reducing waste.

Advantages

- Easy to process—no vulcanization required.

- Short molding cycles and high production efficiency.

- Customizable in hardness, color, and surface finish.

- Compliant with safety standards like RoHS and REACH.

- Cost-effective for mass production.

Disadvantages

- Limited heat resistance: Softens above 100–120°C.

- Poor solvent resistance: Vulnerable to swelling or cracking in contact with fuels.

- Compression set: May deform under long-term pressure.

- Ozone sensitivity: Requires additives for high-ozone environments.

Applications

Consumer Goods

- Shoe soles, soft-grip handles, toys, and kitchenware

Automotive

- Seals, gaskets, mats, and interior trim

Medical & Healthcare

- Tubing, seals, orthopedic supports

Industrial

- Vibration dampers, cable insulation, and tool coatings

Packaging

- Bottle caps, flexible containers

In a narrow sense, we refer to materials based on SBS (Styrene-Butadiene-Styrene) as TPR (Thermoplastic Rubber), and SEBS-based ones as TPE.